2023-05-06

Tag Archives: electric motor with gearbox

China Small Electric Motor Gearbox with Motor worm gear backdrive

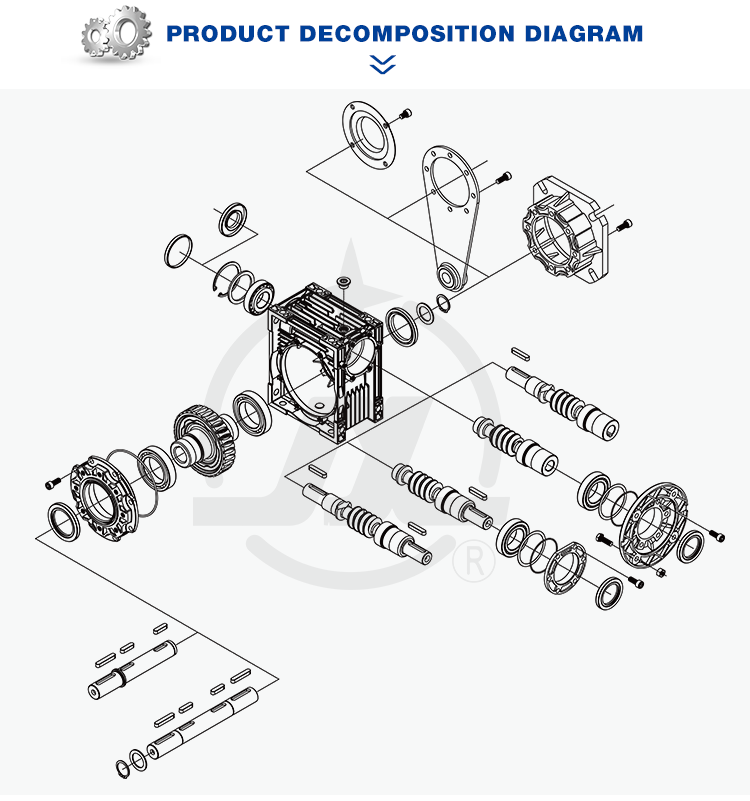

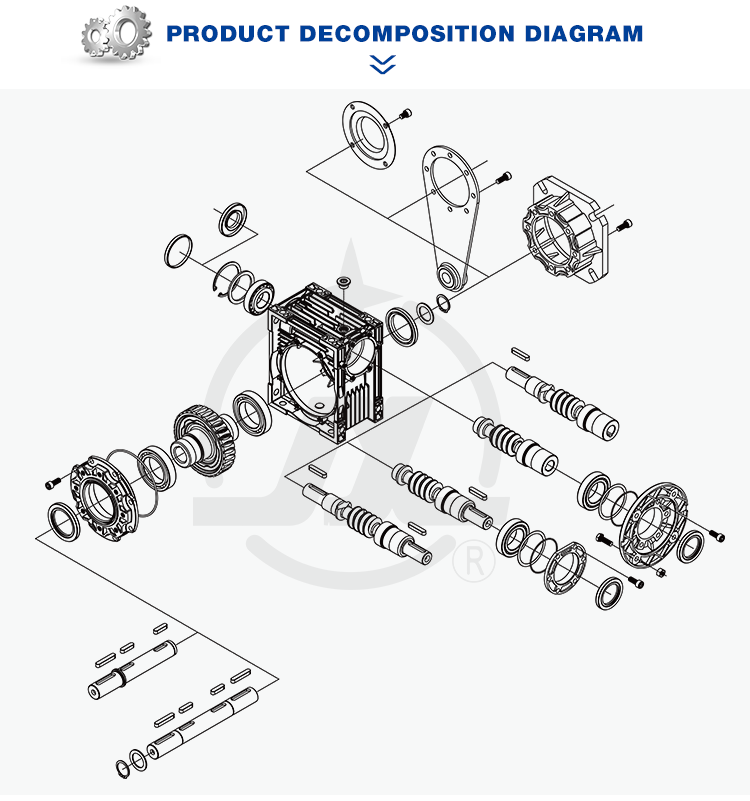

Item Description

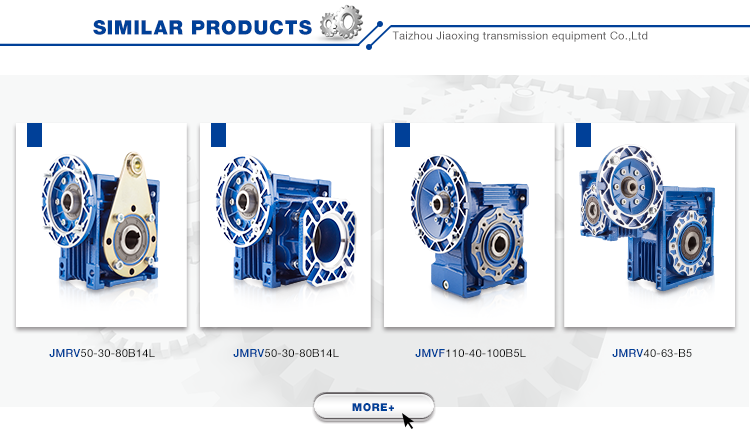

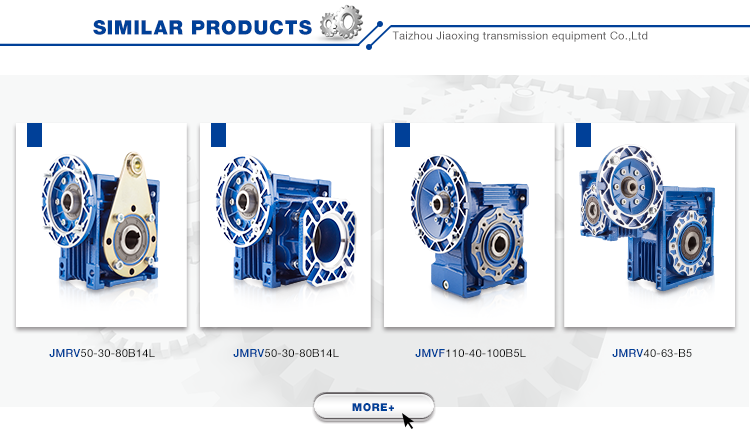

S sequence worm gear box small electric powered motor gearbox

Dimension: S37, S47, S57, S67, S77, S87, S97

Construction: Foot mounted, flange mounted, hollow shaft, sound shaft

Kind: SAZ, SA, SAF, SAZ, SAT, SS, SAS, SFS, SFS, SAFS, S

Specifications

S collection helical-worm equipment reducer

Compact construction, long lifetime,

Big output torque, low sounds

Descriptions:

1. Mix of helical-worm gears, small in dimensions, light bodyweight, compact structure, massive reduction ratio and strong bearing potential&semi

2. Bump gearbox physique area has a cooling effect, minimal temperature increase and minimal sounds&semi

3. Great sealing efficiency and powerful operating setting adaptability&semi

4. Substantial generate precision, notably adapted to the recurrent starts instances&semi

5. Input sorts: Motor immediately connected, the motor belt be a part of or enter shaft coupling flange input.

Requirements

This equipment velocity reducer is a new transmission equipment created & produced by worm- helical equipment transmission principle.

one. Higher mechanical efficiency: ninety four&percnt-ninety eight&percnt &lpardepends on the transmission steps)&semi

2. Enter form: Flange input, direct motor input, shaft input&semi

three. Materials of equipment speed reducer human body: HT250 higher-energy solid iron&semi

four. Supplies of shafts: 42CrMo alloy steel&semi

five. Supplies of gears: 20CrMnTi alloy steel&semi

six. Warmth remedy: Tempering, cementiting, quenching&semi

7. Surface hardness of gears: HRC58° -sixty two ° &semi

eight. Maching precision of gears: 6-5GRADE&semi

9. Manufacturer of bearings: HRB, LYC, ZWZ, NSK&semi

10. Sounds of equipment velocity reducer: sixty-68dB

|

US $50-2,000 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Motor |

|---|---|

| Type: | Helical Worm |

| Output Torque: | 10 to 5000n.M |

| Rated Power: | 0.18kw~22kw |

| Input Speed: | 500rpm~1800rpm |

| Output Speed: | 0.3-150rpm |

###

| Customization: |

Available

|

|---|

|

US $50-2,000 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Motor |

|---|---|

| Type: | Helical Worm |

| Output Torque: | 10 to 5000n.M |

| Rated Power: | 0.18kw~22kw |

| Input Speed: | 500rpm~1800rpm |

| Output Speed: | 0.3-150rpm |

###

| Customization: |

Available

|

|---|

Is a worm gear reducer gearbox right for your application?

If you’re interested in gear reduction and wondering if a worm gear reducer gearbox is right for your application, you’ve come to the right place. This gear reducer gearbox is efficient and compact. In addition, it has small clearances and is easy to install. Let’s take a closer look.

This is a reducer gearbox

Worm reducer gearbox is a type of reduction gear used in machinery. This gear reduces the output speed by changing the ratio of input to output. Gears come in a wide range of sizes and can be made from a variety of materials, including aluminum, cast iron, and stainless steel. Its efficiency depends on the ratio and size of the gears. It is usually used in low speed applications. But it can also be used as an auxiliary braking device for high-speed moving machinery.

When choosing a reduction gear, it’s important to look for models with multiple teeth. Ideally, it will have more teeth than the corresponding sprocket. This will reduce the noise produced by the gears. The maximum number of teeth of the worm gear should be greater than 40.

Worm gears produce less noise and vibration than conventional gears. Also, they are cheaper and smaller than other types of reduction gears. However, worm gears have some limitations that make them less efficient than other types. For example, they do not perform as efficiently as parallel or orthogonal axes, which are much better at transmitting power.

The main disadvantage of worm gears is the difficulty of lubrication. Worm gear reducer gearboxes require more lubrication due to the helical motion of the gears. This means it is less efficient and more prone to wear than a standard gearbox. Helical motion has problems transmitting power and causes sliding friction, also known as sliding wear.

A worm reducer gearbox is a reduction gearbox used to decelerate a high-speed motor to a low-speed output. Worm gear reducer gearboxes produce lower output speeds while maintaining high torque. Its gears are made of bronze or stainless steel and have a right-angle output. The gears are very small compared to other reducer gearboxes, so they can be used in tight spaces and applications where space is limited.

Worm gear reducer gearboxes are an excellent choice for applications requiring high torque and low speeds. These reducer gearboxes are compact, durable and have a long service life. These gearboxes are also compatible with solid and hollow output shafts. This feature eliminates the need for chains or belts, reducing the number of moving parts. Plus, they’re easy to maintain, which means they’re an excellent choice for a variety of applications.

Worm gear reducer gearboxes are also compact, versatile and easy to install. The worm gear itself is made from a single piece of alloy steel. It has a high helix angle and is case hardened and ground for durability. Its six AF hex sockets are designed for easy installation and a wide range of ratios. Worm gear reducer gearboxes are also suitable for manual operation. They are easy to install, compact in design and compatible with a wide range of motors and drives.

Worm reducer gearboxes are often used in industrial settings where a small amount of torque is required to move large objects. They are also useful when space is at a premium. They are compact and easy to install in tight spaces. Worm gears reduce the risk of tripping and are often made of durable materials, making them a popular choice.

Compared with planetary gearboxes, worm gear reducer gearboxes have many advantages. They are quiet, produce less noise, and are more comfortable to use. They are also more energy efficient than their planetary counterparts. Furthermore, they can be combined with other gearboxes and trains to increase their output efficiency.

It is high efficiency

When a worm reducer gearbox is used in a gear-motor, it is critical to note that it is extremely high in efficiency. This type of reducer gearbox is typically much hotter than a hypoid reducer gearbox, which reduces the service life of the gear. The increased thermal stress on the sliding gears results in premature seal wear and leakage. Furthermore, excessive heat causes lubrication to break down and can cause contamination. Helical gear reducer gearboxes are significantly cooler and have a low-maintenance design. Consequently, they can reduce factory downtime and energy costs.

A servo-worm reducer gearbox is an excellent choice for applications requiring high performance, repeatability, and precision positioning. These gear reducer gearboxes have been specifically designed for use with servo motor technology, which provides tight integration of the gear motor. Other advantages of a servo-worm reducer gearbox include reduced angular backlash and longer life.

Hypoid gearmotors offer increased efficiency and allow smaller motors to be used. A 1 HP worm reducer gearbox can produce the same amount of output as a 1/2 HP hypoid reducer gearbox. A Agknx study compared the two types of reducer gearboxes, comparing power, torque, and efficiency. As a result, a 1/2 HP hypoid gearmotor is much cheaper to operate than a 1 HP worm reducer gearbox.

The efficiency of a worm gear reducer gearbox depends on many factors, including the mesh of the gears and losses in the bearings and oil seal lips. The speed and load of the reducer gearbox also have an impact on its efficiency. As a result, worm gear reducer gearboxes should be used with the right type of lubricant.

In a worm gear reducer gearbox, a non-intersecting shaft rotates against a gear, while the output worm gear rotates in a perpendicular direction. This arrangement produces high efficiency while reducing the noise and vibration of the gear motor. This gear reducer gearbox is also quiet and has a low friction coefficient.

It has a low clearance

Worm reducer gearboxes are typically designed with a low clearance, meaning that the worm is not allowed to touch the wheels in the gear arrangement. The lubricant used depends on the size of the gearing, and it is usually ISO 680 or ISO 460. Higher viscosities require special equipment.

Worm gears are popular in machines that need to stop quickly, such as lifts and elevators. The gears and worm are made of a soft material, minimizing backlash and failure rates. They are also popular in heavy-duty machines, such as rock crushers. But while this is an important aspect of their design, there are other factors to consider when choosing a worm gear.

Worm gears have multiple teeth, which allows for greater surface area contact and a better distribution of load. This feature allows for high transmission ratios without sacrificing power. Worm gears can be paired with other gearboxes to increase the overall efficiency of the system.

Worm gears are often used in heavy machinery, including trucks barreling down a deserted highway. They can also be found in packaging machinery, conveyors, and other small machinery. Their unique shape makes them ideal for tight spaces. But they also tend to wear and tear much faster than conventional gears.

It has a high torque to weight ratio

The worm gear reducer gearbox is a versatile gear train that provides a high torque-to-weight ratio. These reducer gearboxes are typically used in applications that require high torque and high gear ratios, such as machine tools. They also have a very compact design, enabling very high gear ratios at low speeds.

Worm gear reducer gearboxes are very quiet, mainly because the input and output shafts are perpendicular to each other. Their low noise level is an advantage compared to planetary gearboxes. Compared with planetary reducer gearboxes, worm gear reducer gearboxes are also relatively cheap.

The worm gear consists of two parts: the helical butt-jointed worm gear and the worm. The screw-butted worm gear is connected to the shaft by a helical thread. The worm gear is a variation of the six-simple machine. The worm is located in the worm wheel, which forces the worm to rotate. It also changes the plane of motion. Worm gears are usually made of steel or brass.

Worm gear reducer gearboxes are one of the most popular types of reducer gearboxes. It provides high torque and high speed ratio in a compact package. These reducer gearboxes are used in many power transmission systems, including elevators, safety gates, conveyor belts, and medical testing equipment.

Worm reducer gearboxes come in a variety of shapes and sizes, including parallel shaft reducer gearboxes and planetary worm reducer gearboxes. They have a high torque-to-weight ratio and are easy to maintain. They are also lightweight and relatively easy to install. This makes them an excellent choice for many applications.

Worms can be assembled using stepped shafts, set screws or dowel pins. However, the worm is subject to a lot of thrust and must be held firmly. This could lead to a rebound. Also, the bearings may come loose and the worm may move. To avoid backlash, make sure the worm gear shaft passes through the midpoint of the worm face width.

editor by czh 2022-12-30

China manufacturer & factory supplier for Input in Arequipa Peru speed 1450rpm min Bwd3 cycloidal drive gearbox ratio 1 10 cycloidal speed reducer with electric motor With high quality best price & service

ISO 9001:2015 certified manufacturer and distributor of roller chains. Varieties of roller chains Maintenance This kind of gear reducer is offered with a long lasting lubrication, so it does not need any kind of upkeep.incorporate ASME/ANSI regular chains, attachment chains, corrosion resistant chains, lube-cost-free chains, plastic chains, cost-free-movement chains, specialty chains and British common chains. ASME/ANSI standard chains are obtainable in big and little pitch, double pitch and leaf styles. Roller chains are used in foodstuff packaging, forklift trucks, oilfield drilling, motorcycles, conveyors and energy transfer applications.If you are fascinated in any of our merchandise or would like to talk about a prospective get, please feel free to speak to us.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Model Title:

-

OEM

- Item NO:

-

Our firm is situated in XiHu HangZhou Zhejiang Province. T

SYF

- Material:

-

Steel

- Bearing:

-

NSK Bearing

- Ratio:

-

eleven~87

- Output torque:

-

26N.m-22920N.m

- Enter velocity:

-

720-2800rpm

- Output velocity:

-

.1-400rpm

- Certification:

-

ISO9001

- Warranty:

-

one-2 years

- Mount Place:

-

Horizontal Foot Mounted Vertical

The EPG Group variety of PTO shafts components contains numerous types of yokes for the relationship of the tractor electricity take-off with recessed push button and/or ball collar and/or ball collar for consistent velocity joints, with the adhering to spline proportions: 1”3/8 Z6 – 1”3/8 Z6 -1”3/8 Z21- 1”3/4 Z6- 1”3/4 Z20

Packaging & Shipping

-

Direct Time

: -

Amount(Parts) one – ten >10 Est. Time(times) fifteen To be negotiated

Online Customization

Product Description

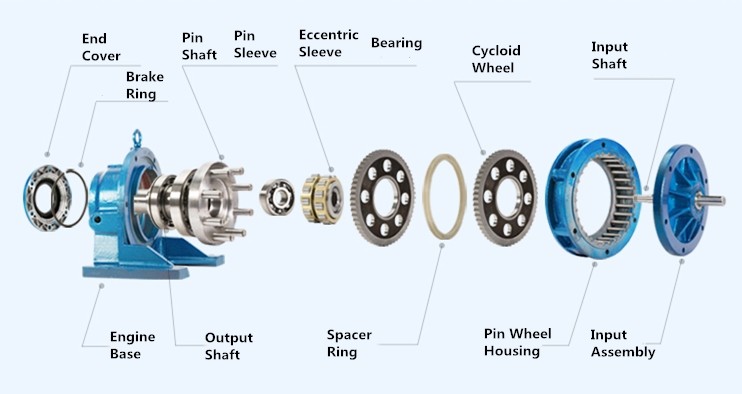

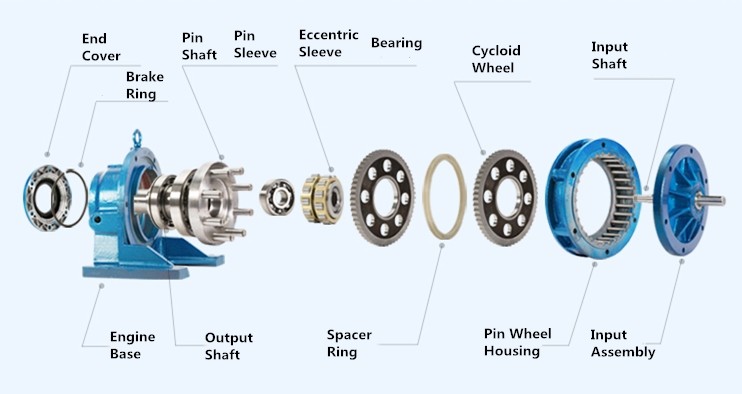

Cycloidal gear reducer is a theory adopted K-H-V Planetary Gear considerably less revolutionary equipment.

Its transmission procedure as follows : enter shaft geared up with a 180-diploma dislocation of the double eccentric sets, changed with two eccentric flip as a roller bearing arm, the development of H-, two cycloid round gap at the centre shall uplink Eccentric Roller Bearings arm, which cycloidal equipment needle spherical and meshing phase, comprising a big difference of the teeth meshing with the gearbox.

|

Dimensions |

X1 |

X2 |

X3 |

X4 |

X5 |

X6 |

X7 |

X8 |

X9 |

|

B09 |

B0 |

B1 |

B2 |

B3 |

B4 |

B5 |

B6 |

||

|

Output Torque N.M |

|||||||||

|

Pace Ratio |

Enter Speed 1500 rpm |

1000 rpm |

|||||||

|

11 |

26 |

forty eight.three |

141.seven |

257.6 |

483. |

708.three |

965.nine |

1787. |

2125.1 |

|

17 |

forty |

74.6 |

149.three |

398.one |

746.four |

1094.7 |

1492.8 |

2761.eight |

3284.3 |

|

23 |

27 |

53.nine |

202. |

296.two |

740.five |

1481.8 |

1481.eight |

3736.5 |

3736.5 |

|

29 |

34 |

sixty seven.9 |

186.seven |

373.5 |

933.7 |

1867.four |

1867.four |

2546.5 |

4711.3 |

|

35 |

forty one |

82 |

225.four |

307.4 |

819.six |

1536.7 |

2253.eight |

3673.four |

5686.five |

|

forty three |

50 |

100.seven |

151. |

377.six |

755.two |

1384.five |

1887.nine |

2768.9 |

3775.8 |

|

fifty nine |

207.two |

380. |

759.9 |

1381.5 |

1899.six |

2590.four |

3799.3 |

||

|

seventy one |

166.three |

332.5 |

623.5 |

1246.nine |

1662.five |

2286. |

4572. |

||

|

87 |

280.one |

764. |

1120.five |

2037.2 |

2037.2 |

7639.five |

|||

Merchandise Qualities

Higher Velocity Ratio and High Effectiveness

One-phase transmission can accomplish a deceleration ratio of 1:87, and the performance is in excess of ninety%. If multi-stage transmission, the deceleration ratio is more substantial.

Compact construction and tiny volume

Since the planetary transmission principle is adopted, the enter shaft and the output shaft are on the exact same axis, so the construction is compact and the volume is small.

Sleek operation and lower sound

Cycloidal pin tooth have several meshing enamel, huge overlap coefficient and smooth system, which boundaries vibration and sounds to a bare minimum.

Reliable use and lengthy provider daily life

Simply because the major components are bearing metal, large energy is acquired by quenching treatment (HRC58-62), and rolling friction is utilised in some transmission contacts, which is sturdy and has prolonged service life.

REDUCER SHAFT

New national normal shaft.

Multi-precision machining, via rigid dynamic and static balance test processes, to make sure the reducer working reduced noise, stability clean.

THICKENING Base

The box entire body is made of HT200 material,which is cleaned by specialist screening and washing gear to make certain that the internal cavity of the box entire body is cleaner with no iron filings.

Cycloid wheel

The cycloid wheel hardened bearing metal,

large toughness, prolonged services daily life of the rolling friction make contact with elements adopt.

Specialist AIR TIGHTNRSS Examination

Semi-Computerized PET Bottle Blowing Equipment Bottle Producing Equipment Bottle Moulding Machine

PET Bottle Producing Machine is suited for generating PET plastic containers and bottles in all styles.

Our Business

HANGZHOU Ever-Electrical power Team, One OF THE Greatest GEARBOX Manufacturing unit IN CHINA, ELECTROMECHANICAL Tools Supply STATION

Our firm is situated in the city of HangZhou, ZheJiang Province of China.

We deal with the goods of electricity transmission, our lines largely go over sequence goods in pace reducers, gearboxes , associated electricial motors and other energy transmission add-ons. Primarily based on the versatile functions, our merchandise can be used in numerous fields: equipment of waste drinking water remedy, dredgers, chemical business, cranes, metallic functioning mills, conveyors, paper market, cement market, cableways and so on.With the excellent top quality and sensible price , our goods appreciate a excellent popularity from buyers and the peers all in excess of the world.

Additionally, the R&D expenditure are annually growing for the purpose of far better assembly the new demands of our customers and adapting the new inclination of the industry.

Based on the concepts of truthfully operating and mutual gain, We sincerely appear forward to cooperating with you.

Software location

Certifications

Packing&Transportion

FAQ

Q1: Are you a investing company or a company ?

A: We are a manufacturer in ZheJiang Province, China. Our company owns the potential of manufacturing, processing,planning and R&D. We welcome your check out.

Q2: How we decide on versions and specs?

A: According to the particular details of the needs from the portion of enquiry, we will suggest the products’ versions on synthesizing the aspects of field of products use, energy, torque arm and ratio…

Q3: How is your price? Can you supply any low cost?

A: Our costs are always competitive. If the buyer can spot a massive purchase, we absolutely will enable price cut.

This autumn: How extended must I wait for the comments right after I ship the enquiry?

A4: We will reply the enquiries with no any hold off, twelve hours at most.

Q5: What is your product warranty time period?

A: We have the certifications of ISO99001,CE, SGS.

Q6: What industries are your gearboxes currently being employed?

A: Our gearboxes are extensively utilized to metallurgical tools, mining products, automation products, foodstuff machinery, packaging products, tobacco products and so on.

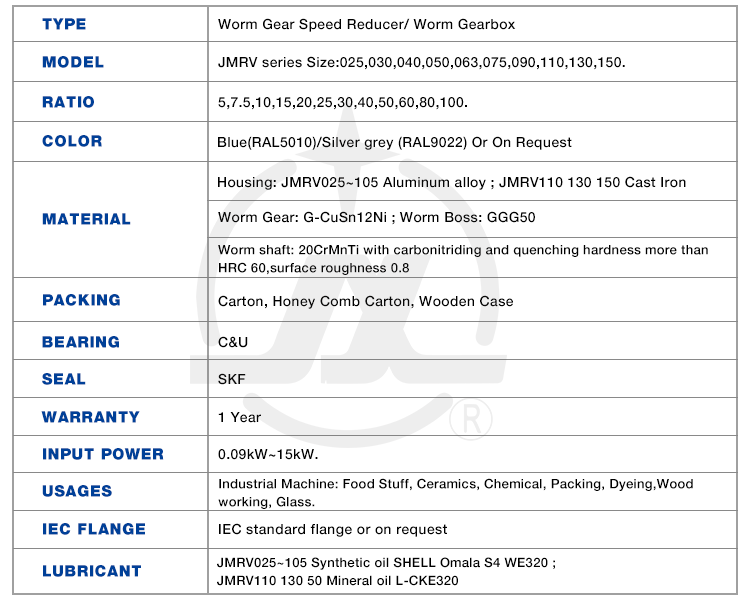

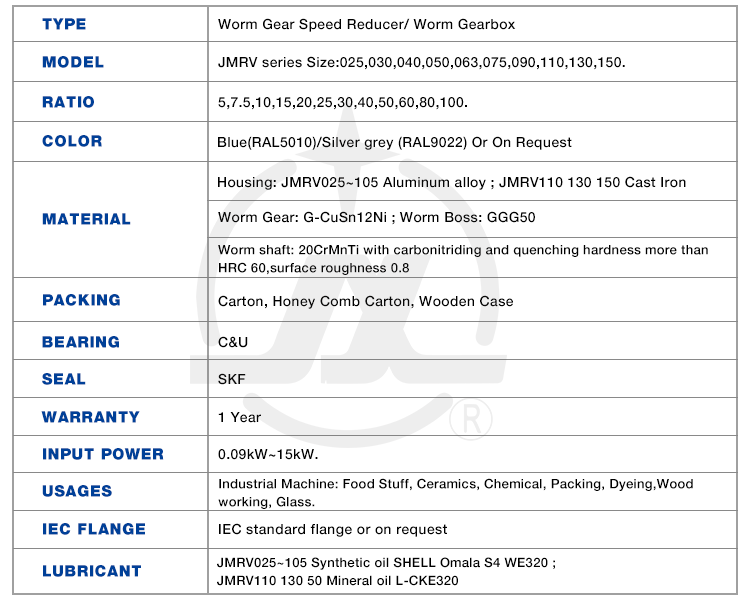

Best China manufacturer & factory Factory in Khon-Kaen Thailand direct small 1:40 ratio electric motor gearbox With high quality best price

we source chromed bar and tubes for hydualic and pheumatic cylinders, pto shaft, agricultural gearboxes and many others.

Overview

Quick Information

- Relevant Industries:

-

Producing Plant

- Gearing Arrangement:

-

worm

- Output Torque:

-

fifteen~1700Nm

- Input Speed:

-

five hundred~2800/min

- Output Pace:

-

five~560/min

- Place of Origin:Zhejiang, China

- Manufacturer Name:

-

OEM

- Product title:

-

tiny 1:forty ratio electric powered motor gearbox

EPG Equipment is situated in XiHu Location HangZhou Zhejiang ,China. It is 30km from our manufacturing unit to HangZhou international airport.

- Application:

-

Foodstuff Things, Ceramics, Chemical, Packing, Dyeing,Wooden operating, Glass.

- Color:

-

Blue(RAL5010)/Silver gray (RAL9022) Or On Request

- Ratio:

-

five,7.5,10,fifteen,twenty,twenty five,thirty,forty,fifty,sixty,80,a hundred.

- Guarantee:

-

1 Yr

Source Potential

- Source Potential:

- 36000 Piece/Parts per Thirty day period

Packaging & Shipping and delivery

- Packaging Details

- Transparent box packaging, or shade box packaging, it also can be tailored.

In shut consultation with the customer, the design and style of specific gearboxes and large-precision gearing elements are separately customized to the technological and operational requirements. For specific specifications such as High Velocity, reduced noise or Higher TORQUE, we build optimum buyer solutions many thanks to our several a long time of knowledge and skills. Additionally, we offer support in the evaluation of load assessments and merchandise engineering optimization. Owing to our steadily developing skills, this results in tailor made high-conclude answers, which we make in-property.

- Port

- Ningbo/Shanghai

The good quality of items is for us and for our buyers of substantial significance. This is why we use European manufactured elements in our merchandise. We also carry out continuous handle of incoming supplies and the control of finished merchandise. In our organization we operate according to ISO 9001.

Online Customization

Factory immediate small 1:forty ratio electric powered motor gearbox

Q1. How to pick a 1:200 ratio gearbox which fulfills our prerequisite?

A1: You can refer to our catalogue to choose the gearbox or we can aid to choose when you give

the complex details of output torque, output velocity and motor parameter and so on.

Q2. How is your price? Can you provide any price reduction?

A2: We will give the best price we can foundation on your requirements and the quantities.

Q3. Do you provide any checking out?

A3: Indeed! We sincerely invite you to check out us! We can choose you from airport, railway station and so on.

Also, we can prepare housing for you. You should allow us know in advanced.

This autumn. When is the greatest time to make contact with you?

A4: You can make contact with us by electronic mail any time, we will reply you as quickly as feasible.

Q5. How extended will it take for the direct time?

A5: For our regular design, make sure you refer to the different item webpages to check the guide time.

For the OEM/ODM merchandise, make sure you make contact with us for additional details.