Product Description

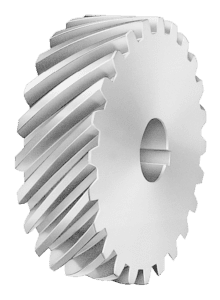

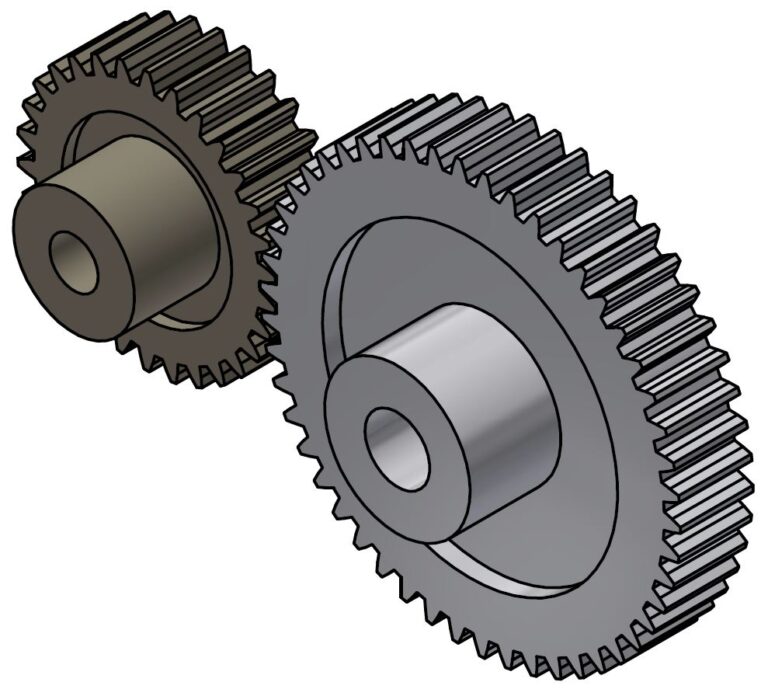

Product introduction

| Modulo | Above 0.8 |

| Numero di Denti | Above 9teeth |

| Angolo d’Elica Helix Angle | Up to 45 |

| bore diameter | Above 6mm |

| axial length | Above 9mm |

| Gear model | Customized gear accoding to customers sample or drawing |

| Processing machine | CNC machine |

| Material | 20CrMnTi/ 20CrMnMo/ 42CrMo/ 45#steel/ 40Cr/ 20CrNi2MoA/304 stainless steel |

| Heat treattment | Carburizing and quenching/ Tempering/ Nitriding/ Carbonitriding/ Induction hardening |

| Hardness | 35-64HRC |

| Qaulity standerd | GB/ DIN/ JIS/ AGMA |

| Accuracy class | 5-8 class |

| Shipping | Sea shipping/ Air shipping/ Express |

My advantages:

1. High quality materials, professional production, high-precision equipment. Customized design and processing;

2. Strong and durable, strong strength, large torque and good comprehensive mechanical properties;

3. High rotation efficiency, stable and smooth transmission, long service life, noise reduction and shock absorption;

4. Focus on gear processing for 20 years.

5. Carburizing and quenching of tooth surface, strong wear resistance, reliable operation and high bearing capacity;

6. The tooth surface can be ground, and the precision is higher after grinding.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Bevel Wheel |

| Material: | Cast Steel |

| Type: | Worm And Wormwheel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you provide examples of machinery that use helical gears?

Helical gears are widely used in various types of machinery and mechanical systems. Their unique tooth geometry and smooth operation make them suitable for applications that require high torque transmission, precision, and low noise levels. Here are some examples of machinery and equipment that commonly utilize helical gears:

- Industrial Gearboxes: Helical gears are extensively employed in industrial gearboxes used in various industries such as manufacturing, mining, oil and gas, and power generation. These gearboxes are responsible for transmitting power and adjusting rotational speed in large machinery and equipment, including conveyors, mixers, crushers, extruders, and heavy-duty pumps.

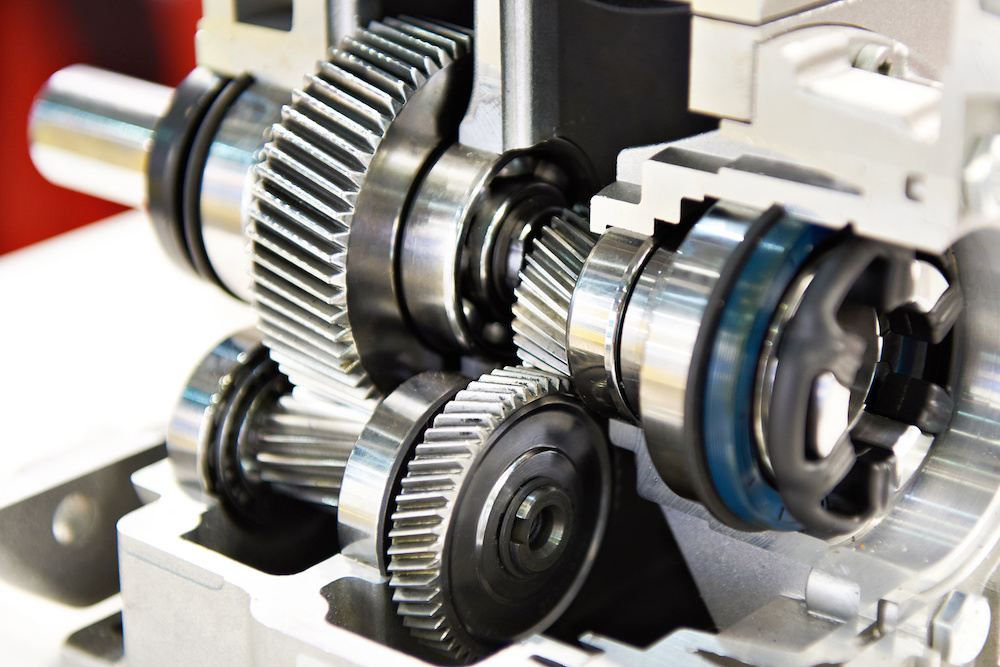

- Automotive Transmissions: Helical gears play a crucial role in automotive transmissions, both manual and automatic. They facilitate the smooth shifting of gears and the transfer of power from the engine to the wheels. Helical gears are commonly found in the main transmission system, differential gears, and gear sets used in the gearbox.

- Machine Tools: Many types of machine tools, such as milling machines, lathes, and grinding machines, rely on helical gears for precise motion control and power transmission. Helical gears are used in the spindle drives, feed mechanisms, and gearboxes of these machines, enabling accurate and efficient metal shaping, cutting, and finishing operations.

- Rotary Compressors: Helical gears are employed in rotary compressors, which are widely used in industries such as refrigeration, HVAC, and pneumatic systems. The helical gears in these compressors help to compress and transfer gases or fluids, generating the desired pressure and flow rates.

- Printing Presses: High-speed printing presses utilize helical gears in their drive systems. The gears enable the precise synchronization of various components, such as rollers, cylinders, and plate cylinders, ensuring accurate paper feeding, ink distribution, and image transfer during the printing process.

- Paper and Pulp Industry: Helical gears are utilized in machinery used in the paper and pulp industry, including paper mills and paperboard manufacturing plants. They are employed in equipment such as pulpers, refiners, stock pumps, and paper machine drives, facilitating the processing, refining, and transportation of pulp and paper materials.

- Construction Equipment: Helical gears are found in various construction machinery, such as cranes, excavators, loaders, and bulldozers. They are used in the drivetrains, swing mechanisms, and hydraulic systems of these machines, providing the necessary torque, speed control, and power transmission capabilities.

- Marine Propulsion Systems: Helical gears are utilized in marine propulsion systems, including marine engines, outboard motors, and ship propulsion systems. They enable efficient power transmission from the engine to the propeller, ensuring smooth and reliable operation of watercraft.

- Wind Turbines: In wind energy applications, helical gears are commonly used in wind turbine gearboxes. They help convert the low-speed rotation of the turbine blades into higher rotational speeds required by the electrical generators, enabling efficient energy generation from wind power.

- Food Processing Machinery: Helical gears find applications in the food processing industry, where they are used in equipment such as mixers, conveyors, extruders, and packaging machines. They facilitate the movement of ingredients, blending, and precise control of processing parameters.

These examples demonstrate the versatility and widespread use of helical gears across various industries and applications. The unique characteristics of helical gears make them suitable for a wide range of machinery that requires smooth, efficient, and reliable power transmission.

How do you retrofit an existing mechanical system with helical gears?

Retrofitting an existing mechanical system with helical gears involves replacing the current gear system with helical gears to improve performance, efficiency, or address specific requirements. The process requires careful planning, analysis, and implementation to ensure a successful retrofit. Here is a detailed explanation of how to retrofit an existing mechanical system with helical gears:

- Assess the Existing System: Begin by thoroughly assessing the existing mechanical system. Understand its design, operating conditions, gear specifications, and performance limitations. Identify the reasons for retrofitting, such as the need for increased load capacity, improved efficiency, noise reduction, or other specific requirements.

- Define Retrofit Objectives: Clearly define the objectives of the retrofit. Determine the specific improvements or modifications desired from the retrofit. This could include increasing torque capacity, reducing backlash, improving gear meshing characteristics, or optimizing gear ratios. Having well-defined objectives will guide the retrofitting process.

- Perform Gear Design and Analysis: Based on the defined objectives, conduct gear design and analysis to determine the appropriate helical gear configuration. Consider factors such as gear size, tooth profile, helix angle, module or diametral pitch, and gear material. Use engineering calculations, software simulations, or consult with gear design experts to ensure the selected helical gears meet the retrofit objectives and are compatible with the existing system.

- Modify Gear Housing and Mounting: In some cases, retrofitting with helical gears may require modifications to the gear housing or mounting arrangements. Ensure that the gear housing can accommodate the helical gears and provide proper alignment and support. Modify or adapt the housing as necessary to ensure a precise fit and alignment of the new gear system.

- Manufacture or Source Helical Gears: Once the gear design is finalized, manufacture or source the helical gears according to the specifications determined during the design phase. Work with experienced gear manufacturers or suppliers who can provide high-quality helical gears that meet the required specifications and performance criteria.

- Installation and Alignment: Remove the existing gears and install the helical gears in the mechanical system. Ensure proper alignment of the gears to maintain smooth operation and minimize wear. Follow recommended installation procedures and torque specifications provided by the gear manufacturer. Consider using alignment tools, such as dial indicators or laser alignment systems, to achieve precise gear alignment.

- Test and Fine-tune: After installation, conduct thorough testing of the retrofit system. Monitor performance, check for any abnormal vibrations, noise, or operating issues. Fine-tune the system as needed, making adjustments to gear meshing, lubrication, or other parameters to optimize performance and ensure the retrofit objectives are met.

- Monitor and Maintain: Once the retrofit is complete, establish a regular monitoring and maintenance schedule. Periodically inspect the helical gears for wear, perform lubrication checks, and address any maintenance requirements. Regular monitoring and maintenance will help ensure the longevity and optimal performance of the retrofit system.

Retrofitting an existing mechanical system with helical gears can significantly enhance its performance, efficiency, and reliability. However, it is essential to carefully plan and execute the retrofitting process to achieve the desired outcomes. Consulting with gear design experts and experienced professionals can provide valuable guidance and expertise throughout the retrofitting process.

What are the applications of helical gears?

Helical gears find wide-ranging applications in various mechanical systems due to their advantageous characteristics and capabilities. Here’s a detailed explanation of the applications of helical gears:

1. Power Transmission: Helical gears are commonly used for power transmission in a wide range of industries. They are employed in machinery and equipment where rotational motion needs to be transmitted between parallel shafts. Examples include gearboxes, industrial machinery, conveyors, and automotive transmissions.

2. Rotary Motion Control: Helical gears are used in applications where precise rotary motion control is required. They provide smooth and accurate motion transfer, making them suitable for applications such as robotics, precision equipment, machine tools, and positioning systems.

3. High Torque Applications: Due to their design and tooth engagement characteristics, helical gears are well-suited for high torque applications. They can efficiently transmit substantial power and handle heavy loads. This makes them suitable for heavy machinery, construction equipment, mining machinery, and marine propulsion systems.

4. Automotive Industry: Helical gears are extensively used in automotive applications. They are found in transmissions, differentials, and powertrain systems, where they facilitate smooth and efficient power transmission while reducing noise and vibration. Helical gears help achieve the desired gear ratios and torque multiplication in vehicles.

5. Machine Tools: Machine tools, such as milling machines, lathes, and gear hobbing machines, utilize helical gears for precise motion control and power transmission. Helical gears enable accurate and smooth rotation of cutting tools and workpieces, contributing to the high precision and quality of machined components.

6. Printing Industry: Helical gears are used in printing presses and other printing equipment. They facilitate the precise movement of paper and printing plates, ensuring accurate registration and high-quality printing results.

7. Textile Industry: In the textile industry, helical gears are employed in various machinery and equipment. They are used in spinning machines, weaving machines, and other textile processing equipment that require precise motion control and power transmission for efficient textile production.

8. Oil and Gas Industry: Helical gears are utilized in oil and gas equipment and machinery. They are found in pumps, compressors, drilling rigs, and other critical components where high torque transmission and reliable motion control are essential for efficient operations.

9. Power Generation: Helical gears play a crucial role in power generation systems. They are employed in wind turbines, hydroelectric generators, and other power generation equipment to transmit rotational motion from the turbine or generator shaft to the electrical generator, ensuring efficient electricity production.

10. General Machinery: Helical gears have diverse applications in general machinery across various industries. They are used in packaging equipment, food processing machinery, material handling systems, and numerous other mechanical systems that require reliable power transmission and precise motion control.

The versatility, load-carrying capacity, and smooth operation of helical gears make them suitable for numerous applications in different industries. The specific design, tooth profile, helix angle, and material selection can be tailored to meet the requirements of each application, ensuring optimal performance and longevity of the gear system.

editor by Dream 2024-04-26

China Good quality Custom Helical Ring Gear Supplier bevel gearbox

Product Description

Product Description

We can produce large forging,casting and welding gears according to customer’s drawings.According to the working conditions and clients’ request,we also can do gear grinding,surface hardening,cemented and quenching,Nitriding and quenching,etc.

|

|

|||||||||||||||||||||||||||||||||||

★★★High Load Capacity: Large helical gear shafts are designed to handle significant loads and transmit high levels of torque. The helical gear design allows for a greater tooth engagement, resulting in improved load distribution and higher load-carrying capacity compared to other gear types.

★★★Smooth and Quiet Operation: Helical gears have a gradual engagement of teeth, which reduces noise and vibration during operation. The helix angle of the teeth helps to distribute the load smoothly, minimizing impact and ensuring a quieter gear system.

★★★Increased Efficiency: The helical gear design provides a larger contact area between the teeth, resulting in higher efficiency compared to other gear types. This leads to reduced power losses and improved overall system efficiency.

★★★Greater Tooth Strength: The helical gear teeth are longer and have a larger surface area compared to spur gears, providing increased tooth strength. This makes large helical gear shafts more resistant to wear and fatigue, allowing them to withstand heavy loads and prolonged use.

★★★Improved Gear Meshing: Helical gears offer a gradual engagement of teeth, which results in a smoother meshing action. This helps to minimize backlash, improve gear accuracy, and reduce the likelihood of tooth damage during gear engagement.

★★★Versatility: Large helical gear shafts can be used in a wide range of applications, including industrial machinery, heavy equipment, marine propulsion systems, and power transmission systems. Their versatility makes them suitable for various industries and sectors.

★★★Reliability and Durability: The use of high-quality materials, precise manufacturing techniques, and rigorous quality control ensures that large helical gear shafts are reliable and durable. They are designed to withstand heavy loads, extreme operating conditions, and long service life.

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Rotary Kiln,Ball Mill |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does a helical gear impact the overall efficiency of a system?

A helical gear has a significant impact on the overall efficiency of a system. Due to their unique design and characteristics, helical gears offer several advantages that contribute to improved efficiency. Here’s a detailed explanation of how a helical gear impacts the overall efficiency of a system:

- Power Transmission: Helical gears provide efficient power transmission due to their inclined tooth design. The helical teeth engage gradually, resulting in a smooth transfer of torque between the gears. This gradual engagement reduces impact and shock loads, minimizing energy losses and improving overall efficiency.

- Load Distribution: The helical tooth profile allows for increased contact area between the gear teeth compared to other gear types. This larger contact area results in improved load distribution across the gear teeth. By distributing the load more evenly, helical gears can handle higher loads without excessive wear and reduce the risk of tooth failure, leading to increased efficiency and reliability.

- Noise and Vibration Reduction: Helical gears operate with less noise and vibration compared to other gear types, such as spur gears. The inclined tooth profile of helical gears helps to minimize gear meshing noise and vibration by distributing the forces along the gear teeth over a larger contact area. Reduced noise and vibration levels contribute to a quieter and smoother operation, indicating lower energy losses and improved overall efficiency.

- Higher Gear Ratios: Helical gears can achieve higher gear ratios compared to other gear types. This capability allows for more precise speed control and torque conversion in various applications. By providing the desired gear ratios, helical gears enable the system to operate at optimal speeds and torque levels, maximizing efficiency and performance.

- Efficient Lubrication: The helical gear design allows for effective lubrication of the gear teeth. The continuous sliding action between the helical teeth assists in distributing the lubricant evenly along the gear contact surfaces. Proper lubrication reduces friction and wear, minimizing energy losses and enhancing the overall efficiency of the gear system.

- Compact Design: Helical gears have a compact design that allows for efficient use of space within a system. The inclined tooth profile enables multiple gear sets to be positioned on parallel or intersecting shafts, facilitating compact gear arrangements. This compactness reduces the overall size and weight of the system while maintaining high efficiency.

- High Precision: Helical gears offer excellent positional accuracy and repeatability. The helical tooth profile ensures precise and consistent gear meshing, resulting in accurate motion control and minimal backlash. This precision contributes to efficient operation, especially in applications requiring precise positioning and synchronization of components.

- Wear Resistance: Helical gears exhibit good wear resistance due to the larger contact area and gradual tooth engagement. The inclined tooth profile helps distribute the load, reducing localized wear and extending the gear’s service life. Reduced wear translates to sustained gear efficiency over time, minimizing the need for frequent replacements and maintenance.

Overall, the design characteristics of helical gears, including smooth power transmission, load distribution, noise reduction, higher gear ratios, efficient lubrication, compactness, precision, and wear resistance, collectively contribute to improved system efficiency. By choosing helical gears appropriately for a given application, engineers can enhance the overall performance, reliability, and energy efficiency of the system.

Can helical gears be used in precision manufacturing equipment?

Yes, helical gears can be used in precision manufacturing equipment, and they are often chosen for their specific advantages in such applications. Helical gears offer several features that make them suitable for precision manufacturing equipment. Here is a detailed explanation:

- Smooth and Precise Operation: Helical gears provide smooth and precise operation due to their gradual engagement of teeth. The helical tooth profile allows for gradual contact between mating gears, resulting in reduced noise, vibration, and backlash. The smooth operation is essential in precision manufacturing equipment where precise motion control and accuracy are required.

- High Load Capacity: Helical gears have high load-carrying capacity due to the larger contact area between the teeth compared to other gear types. This feature is beneficial in precision manufacturing equipment that may encounter heavy loads or high torque requirements. The increased load capacity ensures the gears can withstand the forces involved in precision machining or manufacturing processes.

- Efficiency: Helical gears can achieve high efficiency levels, especially when properly designed and manufactured. The helical tooth profile allows for efficient power transmission with minimal energy losses. In precision manufacturing equipment, high efficiency is desirable to maximize the utilization of input power and minimize heat generation.

- Compact Design: Helical gears have a compact design that allows for efficient use of space in precision manufacturing equipment. The helical gear configuration can provide a higher gear ratio in a smaller package compared to other gear types, making it suitable for equipment with limited space or complex layouts.

- Wide Range of Applications: Helical gears are versatile and can be used in various precision manufacturing equipment. They are commonly found in gearboxes, machine tools, milling machines, lathes, robotics, printing presses, and other equipment where precise motion control and high accuracy are required.

When using helical gears in precision manufacturing equipment, it is crucial to consider factors such as gear quality, material selection, lubrication, and proper alignment. High-quality gear manufacturing processes, accurate gear tooth profiles, and precise gear alignment are essential for achieving the desired precision and performance in manufacturing equipment.

Overall, helical gears are a popular choice in precision manufacturing equipment due to their smooth operation, high load capacity, efficiency, and compact design. Their versatility and ability to deliver precise motion control make them well-suited for various applications in precision manufacturing.

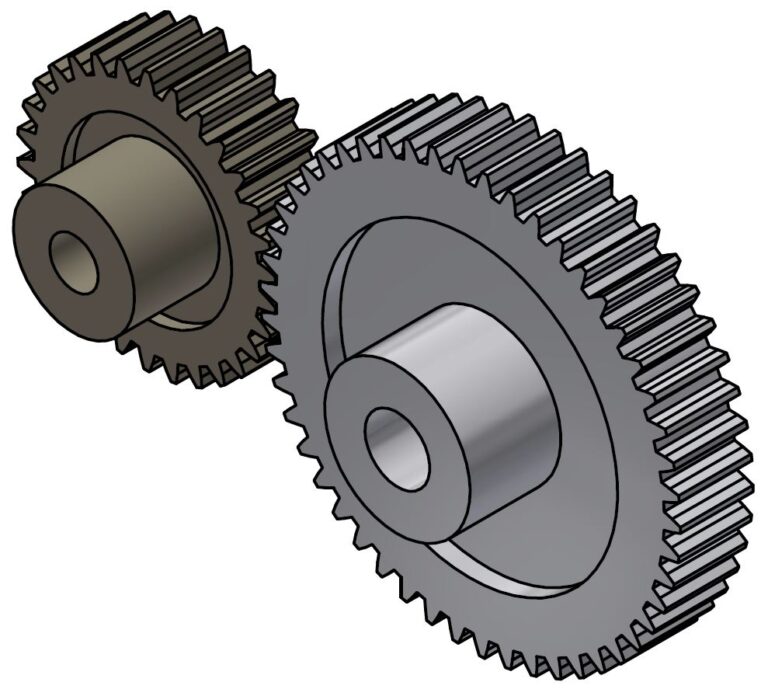

What is a helical gear and how does it work?

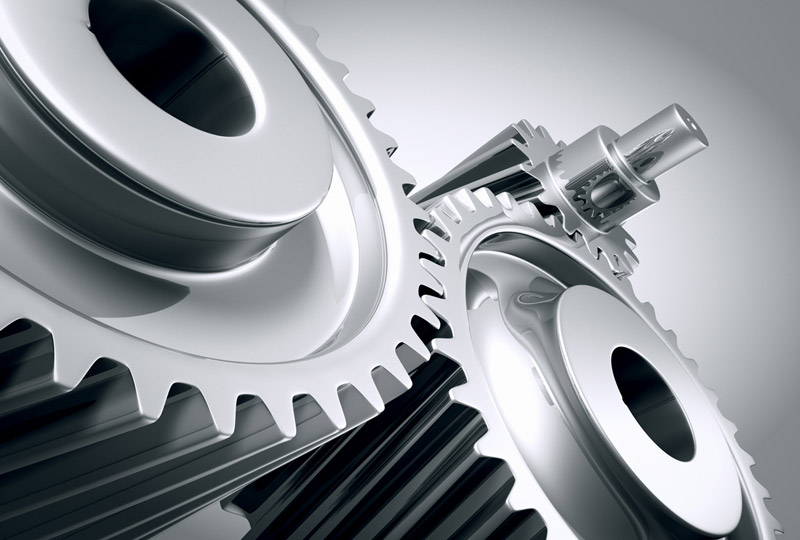

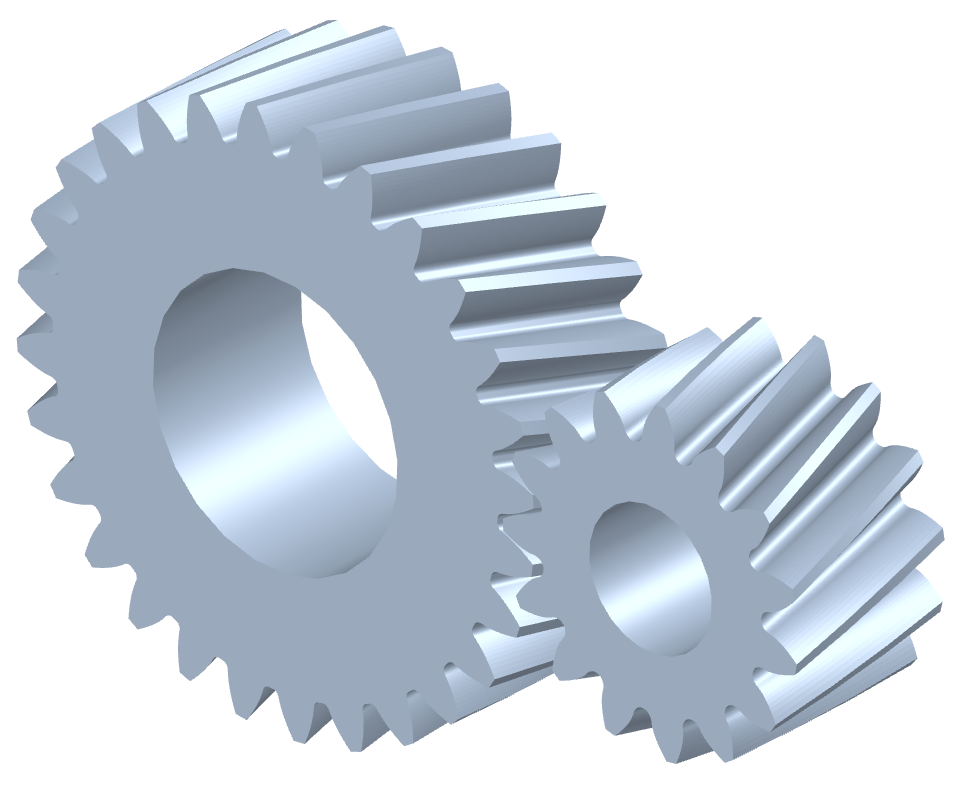

A helical gear is a type of cylindrical gear with teeth that are cut at an angle to the gear axis. It is widely used in various mechanical systems to transmit power and motion between parallel shafts. Here’s a detailed explanation of helical gears and their working principles:

A helical gear consists of a cylindrical shape with teeth that are cut in a helical pattern around the gear’s circumference. The teeth of a helical gear are not perpendicular to the gear axis but are instead aligned at an angle, forming a helix shape. This helix angle allows for gradual engagement and disengagement of the gear teeth, resulting in smoother and quieter operation compared to spur gears.

The working principle of a helical gear involves the transfer of rotational motion and power between parallel shafts. When two helical gears mesh together, their helical teeth gradually come into contact, causing a sliding action as the gears rotate. This sliding action creates both axial and radial forces on the teeth, resulting in a thrust load along the gear axis.

As the helical gears rotate, the sliding action between the teeth causes a force component along the gear axis. This axial force is responsible for generating the thrust load on the gear, which must be properly supported by suitable thrust bearings or other means to ensure smooth and efficient operation.

The helical gear design offers several advantages:

- Smooth and Quiet Operation: The helical teeth engagement allows for a gradual contact between the gear teeth, reducing impact and noise during operation. This results in smoother and quieter gear performance compared to spur gears.

- Increased Load-Carrying Capacity: The helical gear design provides greater tooth contact compared to spur gears. This increased contact area allows helical gears to transmit higher loads and handle greater torque without experiencing excessive wear or tooth failure.

- Parallel Shaft Operation: Helical gears are primarily used for transmitting power and motion between parallel shafts. By meshing two helical gears on parallel shafts, rotational motion can be efficiently transmitted from one shaft to the other with a constant speed ratio.

- Ability to Transmit Motion at Various Angles: While helical gears are commonly used for parallel shaft applications, they can also be used to transmit motion at non-parallel shaft angles by using a combination of helical gears or by incorporating additional components such as bevel gears.

It is important to consider a few factors when using helical gears:

- Helix Angle: The helix angle determines the degree of tooth engagement and sliding action. A higher helix angle increases the smoothness of operation but also introduces a larger axial force and thrust load on the gear.

- Direction of Helix: Helical gears can have either a right-hand or left-hand helix. When two helical gears mesh, they must have opposite helix directions to ensure proper engagement.

- Lubrication: Due to the sliding action between helical gear teeth, proper lubrication is crucial to minimize friction, wear, and heat generation. Adequate lubrication helps ensure the longevity and efficiency of the gear system.

In summary, a helical gear is a cylindrical gear with teeth cut in a helical pattern. It operates by gradually engaging and disengaging the teeth, resulting in smooth and quiet operation. Helical gears are widely used in various mechanical systems for parallel shaft applications, providing high load-carrying capacity and efficient power transmission.

editor by Dream 2024-04-26

China Best Sales Large Double Helical Nylon Plastic Gear gear patrol

Product Description

Quick Details

Place of Origin: China (Mainland) Method: precision injection mold

Model Number: OEM transformer parts mold plastic material: ABS,PA66, PAT, PVC, nylon

Shaping Mode: Nylon, Plastic Injection mould Product: transformer parts mold

Certification: ISO9shots Product name: nylon parts

Surface treatment: Plating, printing, powder, etc Size: Customized Size

Technical Data

Material: Plastic nylon

Physical Properties

| Tensile strength MPa | 60~80 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Elongation at break % | 2.2 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Bending strength MPa | 1/8822 0571 -60863016 http://chinainsulation /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can you provide examples of machinery that use helical gears?Helical gears are widely used in various types of machinery and mechanical systems. Their unique tooth geometry and smooth operation make them suitable for applications that require high torque transmission, precision, and low noise levels. Here are some examples of machinery and equipment that commonly utilize helical gears:

These examples demonstrate the versatility and widespread use of helical gears across various industries and applications. The unique characteristics of helical gears make them suitable for a wide range of machinery that requires smooth, efficient, and reliable power transmission.

Can helical gears be used in both horizontal and vertical orientations?Yes, helical gears can be used in both horizontal and vertical orientations. The design and characteristics of helical gears make them versatile and suitable for various orientations and applications. Here’s a detailed explanation of why helical gears can be used in both horizontal and vertical orientations:

In summary, helical gears are versatile and can be used in both horizontal and vertical orientations. Their load distribution capabilities, ability to be properly lubricated, suitable bearing support, and the importance of alignment and mounting make them suitable for various applications and orientations. By considering specific factors related to the orientation, engineers can ensure the reliable and efficient performance of helical gears in both horizontal and vertical arrangements.

How do helical gears differ from other types of gears?Helical gears possess distinct characteristics that set them apart from other types of gears. Here’s a detailed explanation of how helical gears differ from other gear types: 1. Tooth Orientation: Unlike spur gears, which have teeth perpendicular to the gear axis, helical gears have teeth that are cut at an angle to the gear axis. This helical tooth orientation enables gradual engagement and disengagement of the gear teeth, resulting in smoother and quieter operation. 2. Contact Pattern: Helical gears have a larger contact area compared to spur gears. The helical tooth design allows for multiple teeth to be in contact simultaneously, distributing the load across a broader surface. This increased contact pattern enhances load-carrying capacity and improves the gear’s ability to transmit higher torque. 3. Tooth Engagement: In helical gears, the teeth gradually mesh as they come into contact during rotation. This gradual engagement reduces the impact and noise typically associated with spur gears. The sliding action between the helical teeth also generates axial forces, resulting in a thrust load along the gear axis. 4. Load Distribution: The helical tooth orientation enables load distribution along the tooth face. This characteristic helps minimize localized stress concentrations and tooth wear, resulting in improved gear durability and longevity. 5. Power Transmission Efficiency: Helical gears offer high power transmission efficiency due to their larger contact area and gradual tooth engagement. The sliding action between the teeth introduces some axial force and axial thrust, which must be properly supported, but overall, helical gears are efficient in transmitting power. 6. Parallel Shaft Alignment: Helical gears are primarily used for parallel shaft applications. They transmit motion and power between parallel shafts with a constant speed ratio. Other gear types, such as bevel gears or worm gears, are better suited for non-parallel shaft arrangements or specific motion requirements. 7. Noise and Vibration: Compared to spur gears, helical gears produce less noise and vibration due to their gradual tooth engagement. The helical tooth design reduces the impact and noise caused by abrupt contact between gear teeth, resulting in smoother and quieter operation. 8. Manufacturing Complexity: Helical gears are more complex to manufacture compared to spur gears due to the helical tooth profile. The angled teeth require specialized cutting tools and machining processes. This complexity can affect the manufacturing cost and lead time of helical gears. 9. Axial Thrust Load: Helical gears generate axial forces and thrust loads due to the sliding action between the teeth. This axial thrust must be considered and properly supported in the gear system design to ensure smooth operation and prevent excessive wear or failure. 10. Application Range: Helical gears are versatile and find applications across various industries. They are commonly used in power transmission, robotics, machine tools, automotive systems, and other mechanical systems that require precise motion control and high torque transmission. In summary, helical gears differ from other gear types in terms of tooth orientation, contact pattern, tooth engagement, load distribution, power transmission efficiency, shaft alignment suitability, noise and vibration characteristics, manufacturing complexity, axial thrust load, and application range. These unique characteristics make helical gears well-suited for specific applications where smooth operation, high load-carrying capacity, and precise motion control are required.

China Standard Custom Large Modulus Helical Gear Driving Gear gear ratio calculatorProduct Description

Product Parameters

Company Profile

Application Field

FAQ

1. why should you buy products from us not from other suppliers? /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do you prevent backlash and gear play in a helical gear mechanism?In a helical gear mechanism, preventing backlash and gear play is crucial to ensure accurate motion control, minimize vibration, and maintain the overall efficiency of the system. Here’s a detailed explanation of how to prevent backlash and gear play in a helical gear mechanism:

By implementing these preventive measures, engineers can effectively minimize backlash and gear play in a helical gear mechanism. This results in improved precision, reduced vibration, and enhanced overall efficiency of the gear system.

Can helical gears be used in precision manufacturing equipment?Yes, helical gears can be used in precision manufacturing equipment, and they are often chosen for their specific advantages in such applications. Helical gears offer several features that make them suitable for precision manufacturing equipment. Here is a detailed explanation:

When using helical gears in precision manufacturing equipment, it is crucial to consider factors such as gear quality, material selection, lubrication, and proper alignment. High-quality gear manufacturing processes, accurate gear tooth profiles, and precise gear alignment are essential for achieving the desired precision and performance in manufacturing equipment. Overall, helical gears are a popular choice in precision manufacturing equipment due to their smooth operation, high load capacity, efficiency, and compact design. Their versatility and ability to deliver precise motion control make them well-suited for various applications in precision manufacturing.

What are the applications of helical gears?Helical gears find wide-ranging applications in various mechanical systems due to their advantageous characteristics and capabilities. Here’s a detailed explanation of the applications of helical gears: 1. Power Transmission: Helical gears are commonly used for power transmission in a wide range of industries. They are employed in machinery and equipment where rotational motion needs to be transmitted between parallel shafts. Examples include gearboxes, industrial machinery, conveyors, and automotive transmissions. 2. Rotary Motion Control: Helical gears are used in applications where precise rotary motion control is required. They provide smooth and accurate motion transfer, making them suitable for applications such as robotics, precision equipment, machine tools, and positioning systems. 3. High Torque Applications: Due to their design and tooth engagement characteristics, helical gears are well-suited for high torque applications. They can efficiently transmit substantial power and handle heavy loads. This makes them suitable for heavy machinery, construction equipment, mining machinery, and marine propulsion systems. 4. Automotive Industry: Helical gears are extensively used in automotive applications. They are found in transmissions, differentials, and powertrain systems, where they facilitate smooth and efficient power transmission while reducing noise and vibration. Helical gears help achieve the desired gear ratios and torque multiplication in vehicles. 5. Machine Tools: Machine tools, such as milling machines, lathes, and gear hobbing machines, utilize helical gears for precise motion control and power transmission. Helical gears enable accurate and smooth rotation of cutting tools and workpieces, contributing to the high precision and quality of machined components. 6. Printing Industry: Helical gears are used in printing presses and other printing equipment. They facilitate the precise movement of paper and printing plates, ensuring accurate registration and high-quality printing results. 7. Textile Industry: In the textile industry, helical gears are employed in various machinery and equipment. They are used in spinning machines, weaving machines, and other textile processing equipment that require precise motion control and power transmission for efficient textile production. 8. Oil and Gas Industry: Helical gears are utilized in oil and gas equipment and machinery. They are found in pumps, compressors, drilling rigs, and other critical components where high torque transmission and reliable motion control are essential for efficient operations. 9. Power Generation: Helical gears play a crucial role in power generation systems. They are employed in wind turbines, hydroelectric generators, and other power generation equipment to transmit rotational motion from the turbine or generator shaft to the electrical generator, ensuring efficient electricity production. 10. General Machinery: Helical gears have diverse applications in general machinery across various industries. They are used in packaging equipment, food processing machinery, material handling systems, and numerous other mechanical systems that require reliable power transmission and precise motion control. The versatility, load-carrying capacity, and smooth operation of helical gears make them suitable for numerous applications in different industries. The specific design, tooth profile, helix angle, and material selection can be tailored to meet the requirements of each application, ensuring optimal performance and longevity of the gear system.

China manufacturer High Quality Customized Spur Gear Worm Gear Helical Gear hypoid bevel gearProduct Description

Product Description High Precision Customized Transmission Gear Helical Gear for Various Machinery.

Our Product Range

About Us HangZhou CHINAMFG machinery parts manufacturing was founded with the mission of supplying world class forging products at the best prices. We have a strong engineering team to ensure the quality stability for our customers’ projects. All our engineers have more than 10 years of engineering experience and are specialized in metallurgy, forging, heat treatment, NDT, machining and production testing respectively. For any forging product, only if you supply a sample or operating requirements, our engineers will design the optimal forging process and subsequent testing or manufacturing process for your product. We have been achieving our mission and delivering the most cost-effective, highest quality solutions to our customers. Our quality control begins from raw material, forging, heat treatment, semi-finished machining, final machining till assembly, each step is controlled strictly by our engineers, all of them have 10+ years of engineering experience and are specialized in metallurgy, forging, heat treatment, NDT, machining and production testing respectively. Contact Us

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What is the purpose of using helical gears in power transmission?Helical gears are commonly used in power transmission systems for various purposes. Here’s a detailed explanation of the purpose and advantages of using helical gears in power transmission:

In summary, the purpose of using helical gears in power transmission is to achieve smooth and efficient power transfer, high torque transmission, variable speed control, noise and vibration reduction, compact design, and high reliability. These advantages make helical gears widely used in various industries, including automotive, manufacturing, energy, and many other applications that require reliable and efficient power transmission.

Can helical gears be used in precision manufacturing equipment?Yes, helical gears can be used in precision manufacturing equipment, and they are often chosen for their specific advantages in such applications. Helical gears offer several features that make them suitable for precision manufacturing equipment. Here is a detailed explanation:

When using helical gears in precision manufacturing equipment, it is crucial to consider factors such as gear quality, material selection, lubrication, and proper alignment. High-quality gear manufacturing processes, accurate gear tooth profiles, and precise gear alignment are essential for achieving the desired precision and performance in manufacturing equipment. Overall, helical gears are a popular choice in precision manufacturing equipment due to their smooth operation, high load capacity, efficiency, and compact design. Their versatility and ability to deliver precise motion control make them well-suited for various applications in precision manufacturing.

What are the applications of helical gears?Helical gears find wide-ranging applications in various mechanical systems due to their advantageous characteristics and capabilities. Here’s a detailed explanation of the applications of helical gears: 1. Power Transmission: Helical gears are commonly used for power transmission in a wide range of industries. They are employed in machinery and equipment where rotational motion needs to be transmitted between parallel shafts. Examples include gearboxes, industrial machinery, conveyors, and automotive transmissions. 2. Rotary Motion Control: Helical gears are used in applications where precise rotary motion control is required. They provide smooth and accurate motion transfer, making them suitable for applications such as robotics, precision equipment, machine tools, and positioning systems. 3. High Torque Applications: Due to their design and tooth engagement characteristics, helical gears are well-suited for high torque applications. They can efficiently transmit substantial power and handle heavy loads. This makes them suitable for heavy machinery, construction equipment, mining machinery, and marine propulsion systems. 4. Automotive Industry: Helical gears are extensively used in automotive applications. They are found in transmissions, differentials, and powertrain systems, where they facilitate smooth and efficient power transmission while reducing noise and vibration. Helical gears help achieve the desired gear ratios and torque multiplication in vehicles. 5. Machine Tools: Machine tools, such as milling machines, lathes, and gear hobbing machines, utilize helical gears for precise motion control and power transmission. Helical gears enable accurate and smooth rotation of cutting tools and workpieces, contributing to the high precision and quality of machined components. 6. Printing Industry: Helical gears are used in printing presses and other printing equipment. They facilitate the precise movement of paper and printing plates, ensuring accurate registration and high-quality printing results. 7. Textile Industry: In the textile industry, helical gears are employed in various machinery and equipment. They are used in spinning machines, weaving machines, and other textile processing equipment that require precise motion control and power transmission for efficient textile production. 8. Oil and Gas Industry: Helical gears are utilized in oil and gas equipment and machinery. They are found in pumps, compressors, drilling rigs, and other critical components where high torque transmission and reliable motion control are essential for efficient operations. 9. Power Generation: Helical gears play a crucial role in power generation systems. They are employed in wind turbines, hydroelectric generators, and other power generation equipment to transmit rotational motion from the turbine or generator shaft to the electrical generator, ensuring efficient electricity production. 10. General Machinery: Helical gears have diverse applications in general machinery across various industries. They are used in packaging equipment, food processing machinery, material handling systems, and numerous other mechanical systems that require reliable power transmission and precise motion control. The versatility, load-carrying capacity, and smooth operation of helical gears make them suitable for numerous applications in different industries. The specific design, tooth profile, helix angle, and material selection can be tailored to meet the requirements of each application, ensuring optimal performance and longevity of the gear system.

China best M1.75 Induction Hardened High Hardness Helical Custom Gears supplierProduct Description

Product Description

Detailed Photos Test Inspection steps before delivery: Use GO/Nogo inspect hole—Use micrometer check dimensions—Next use stiffness detection system inspect hardness–Finally use CMM inspect precision Packaging & Shipping

Company Profile

ZheJiang Haorongshengye Electrical Equipment Co., Ltd. 1. Was founded in 2008 “Credibility Supremacy, and Customer First” “High quality products, and Excellent Service” “Being Honesty, Doing the Best, and Long-lasting Development” “Develop to be a leader in the power transmission parts industry in the world”

Main products Machines

Exbihition

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Are helical gears suitable for high-torque applications?Helical gears are indeed well-suited for high-torque applications. Their design features and characteristics make them capable of handling significant torque loads without compromising performance or durability. Here’s a detailed explanation of why helical gears are suitable for high-torque applications:

In summary, helical gears are well-suited for high-torque applications due to their inclined tooth profile, large contact ratio, high load-carrying capacity, gradual tooth engagement, efficient power transmission, and ability to handle variable torque. These characteristics make helical gears reliable and durable in demanding industrial scenarios where high torque levels are encountered.

What are the environmental considerations when using helical gears?When using helical gears, several environmental considerations should be taken into account. These considerations primarily focus on reducing the environmental impact associated with gear manufacturing, operation, and maintenance. Here is a detailed explanation of the environmental considerations when using helical gears:

By considering these environmental factors when using helical gears, manufacturers and users can minimize the environmental impact associated with gear production, operation, and disposal. Implementing sustainable practices not only helps protect the environment but also promotes resource efficiency and long-term economic viability.

How do helical gears differ from other types of gears?Helical gears possess distinct characteristics that set them apart from other types of gears. Here’s a detailed explanation of how helical gears differ from other gear types: 1. Tooth Orientation: Unlike spur gears, which have teeth perpendicular to the gear axis, helical gears have teeth that are cut at an angle to the gear axis. This helical tooth orientation enables gradual engagement and disengagement of the gear teeth, resulting in smoother and quieter operation. 2. Contact Pattern: Helical gears have a larger contact area compared to spur gears. The helical tooth design allows for multiple teeth to be in contact simultaneously, distributing the load across a broader surface. This increased contact pattern enhances load-carrying capacity and improves the gear’s ability to transmit higher torque. 3. Tooth Engagement: In helical gears, the teeth gradually mesh as they come into contact during rotation. This gradual engagement reduces the impact and noise typically associated with spur gears. The sliding action between the helical teeth also generates axial forces, resulting in a thrust load along the gear axis. 4. Load Distribution: The helical tooth orientation enables load distribution along the tooth face. This characteristic helps minimize localized stress concentrations and tooth wear, resulting in improved gear durability and longevity. 5. Power Transmission Efficiency: Helical gears offer high power transmission efficiency due to their larger contact area and gradual tooth engagement. The sliding action between the teeth introduces some axial force and axial thrust, which must be properly supported, but overall, helical gears are efficient in transmitting power. 6. Parallel Shaft Alignment: Helical gears are primarily used for parallel shaft applications. They transmit motion and power between parallel shafts with a constant speed ratio. Other gear types, such as bevel gears or worm gears, are better suited for non-parallel shaft arrangements or specific motion requirements. 7. Noise and Vibration: Compared to spur gears, helical gears produce less noise and vibration due to their gradual tooth engagement. The helical tooth design reduces the impact and noise caused by abrupt contact between gear teeth, resulting in smoother and quieter operation. 8. Manufacturing Complexity: Helical gears are more complex to manufacture compared to spur gears due to the helical tooth profile. The angled teeth require specialized cutting tools and machining processes. This complexity can affect the manufacturing cost and lead time of helical gears. 9. Axial Thrust Load: Helical gears generate axial forces and thrust loads due to the sliding action between the teeth. This axial thrust must be considered and properly supported in the gear system design to ensure smooth operation and prevent excessive wear or failure. 10. Application Range: Helical gears are versatile and find applications across various industries. They are commonly used in power transmission, robotics, machine tools, automotive systems, and other mechanical systems that require precise motion control and high torque transmission. In summary, helical gears differ from other gear types in terms of tooth orientation, contact pattern, tooth engagement, load distribution, power transmission efficiency, shaft alignment suitability, noise and vibration characteristics, manufacturing complexity, axial thrust load, and application range. These unique characteristics make helical gears well-suited for specific applications where smooth operation, high load-carrying capacity, and precise motion control are required.

China factory Manufacturer Price 45# Steel Worm Gear with 20 Pressure Angle manufacturerProduct Description

Manufacturer Price 45# Steel Worm Gear With 20 Pressure Angle The 2 shafts of the worm gear drive are perpendicular to each other; the worm can be regarded as a helix with 1 tooth (single head) or several teeth (multipeheads) wound along the helix on the cylinder, and the worm gear is like a helical gear, but its teeth enclose the worm. During meshing, 1 turn of the worm will drive (multi-head worm), so the speed ratio of the worm gear transmission i=the number of heads of the worm Z1/ the number of the worm wheel teeth Z2. Product Description

Company Profile Packaging & Shipping FAQ

If you are interested in our products, please tell us which materials, type, width, length u want. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What lubrication is required for a worm gear?The lubrication requirements for a worm gear system are crucial to ensure smooth operation, reduce friction, prevent wear, and extend the lifespan of the gears. The specific lubrication needed may vary depending on factors such as the application, operating conditions, gear materials, and manufacturer recommendations. Here are some key considerations regarding lubrication for a worm gear:

It’s important to note that the lubrication requirements may vary for different worm gear applications, such as automotive, industrial machinery, or marine systems. Additionally, environmental factors such as dust, moisture, or chemical exposure should be considered when selecting a lubricant and establishing a lubrication maintenance plan. Always refer to the gear manufacturer’s recommendations and guidelines for the specific lubrication requirements of your worm gear system. Adhering to proper lubrication practices helps ensure smooth and reliable operation, minimizes wear, and maximizes the gear system’s longevity.

How do you address noise and vibration issues in a worm gear system?Noise and vibration issues can arise in a worm gear system due to various factors such as misalignment, improper lubrication, gear wear, or resonance. Addressing these issues is important to ensure smooth and quiet operation of the system. Here’s a detailed explanation of how to address noise and vibration issues in a worm gear system: 1. Misalignment correction: Misalignment between the worm and the worm wheel can cause noise and vibration. Ensuring proper alignment of the gears by adjusting their positions and alignment tolerances can help reduce these issues. Precise alignment minimizes tooth contact errors and improves the meshing efficiency, resulting in reduced noise and vibration levels. 2. Lubrication optimization: Inadequate or improper lubrication can lead to increased friction and wear, resulting in noise and vibration. Using the correct lubricant with the appropriate viscosity and additives, and ensuring proper lubrication intervals, can help reduce friction and dampen vibrations. Regular lubricant analysis and replenishment can also prevent excessive wear and maintain optimal performance. 3. Gear inspection and replacement: Wear and damage to the gear teeth can contribute to noise and vibration problems. Regular inspection of the worm gear system allows for early detection of any worn or damaged teeth. Timely replacement of worn gears or damaged components helps maintain the integrity of the gear mesh and reduces noise and vibration levels. 4. Noise reduction measures: Various noise reduction measures can be implemented to minimize noise in a worm gear system. These include using noise-dampening materials or coatings, adding sound insulation or vibration-absorbing pads to the housing, and incorporating noise-reducing features in the gear design, such as profile modifications or helical teeth. These measures help attenuate noise and vibration transmission and improve overall system performance. 5. Resonance mitigation: Resonance, which occurs when the natural frequency of the system matches the excitation frequency, can amplify noise and vibration. To mitigate resonance, design modifications such as changing gear stiffness, altering the system’s natural frequencies, or adding damping elements can be considered. Analytical tools like finite element analysis (FEA) can help identify resonant frequencies and guide the design changes to reduce vibration and noise. 6. Isolation and damping: Isolation and damping techniques can be employed to minimize noise and vibration transmission to the surrounding structures. This can involve using resilient mounts or isolators to separate the gear system from the rest of the equipment or incorporating damping materials or devices within the gear housing to absorb vibrations and reduce noise propagation. 7. Tightening and securing: Loose or improperly tightened components can generate noise and vibration. Ensuring that all fasteners, bearings, and other components are properly tightened and secured eliminates sources of vibration and reduces noise. Regular inspections and maintenance should include checking for loose or worn-out parts and addressing them promptly. Addressing noise and vibration issues in a worm gear system often requires a systematic approach that considers multiple factors. The specific measures employed may vary depending on the nature of the problem, the operating conditions, and the desired performance objectives. Collaborating with experts in gear design, vibration analysis, or noise control can be beneficial in identifying and implementing effective solutions.

How do you choose the right size worm gear for your application?Choosing the right size worm gear for your application involves considering several factors to ensure optimal performance and longevity. Here are the key considerations: Load Requirements:Determine the maximum load that the worm gear will need to transmit. This includes both the torque (rotational force) and the axial load (force along the axis of the gear). Calculate or estimate the peak and continuous loads that the gear will experience during operation. Consider factors such as shock loads, dynamic forces, and variations in load conditions. This information will help determine the required load-carrying capacity of the worm gear. Gear Ratio:Determine the desired gear ratio for your application. The gear ratio determines the speed reduction and torque multiplication provided by the worm gear system. Consider the specific requirements of your application, such as the desired output speed and the torque needed to drive the load. Select a worm gear with a gear ratio that meets your application’s requirements while considering the limitations of the available gear options. Efficiency:Consider the efficiency requirements of your application. Worm gears typically have lower efficiency compared to other types of gears due to the sliding action between the worm and worm wheel. If efficiency is critical for your application, choose a worm gear design and materials that offer higher efficiency, such as a double enveloping worm gear. Space Constraints:Evaluate the available space for the worm gear assembly in your application. Consider the dimensions of the worm gear, including the diameter, length, and mounting requirements. Ensure that the chosen worm gear can fit within the available space without compromising other components or functionality. Speed and Operating Conditions:Consider the operating speed and environmental conditions in which the worm gear will operate. Some worm gears have speed limitations due to factors such as heat generation and lubrication requirements. Ensure that the selected worm gear is suitable for the anticipated speed range and can withstand the temperature, humidity, and other environmental factors of your application. Manufacturing Standards and Quality:Select a worm gear that conforms to recognized manufacturing standards and quality requirements. Look for worm gears from reputable manufacturers that offer reliable and durable products. Consider factors such as material quality, surface finish, and precision in the gear manufacturing process. By carefully evaluating these factors and considering the specific requirements of your application, you can choose the right size worm gear that meets your performance, load, and space requirements, resulting in a reliable and efficient gear system.

China manufacturer High Precision Helical Steel Straight Bevel Gear bevel spiral gearProduct Description

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Are helical gears suitable for high-torque applications?Helical gears are indeed well-suited for high-torque applications. Their design features and characteristics make them capable of handling significant torque loads without compromising performance or durability. Here’s a detailed explanation of why helical gears are suitable for high-torque applications:

In summary, helical gears are well-suited for high-torque applications due to their inclined tooth profile, large contact ratio, high load-carrying capacity, gradual tooth engagement, efficient power transmission, and ability to handle variable torque. These characteristics make helical gears reliable and durable in demanding industrial scenarios where high torque levels are encountered.

How do you calculate the efficiency of a helical gear?The efficiency of a helical gear can be calculated by comparing the power input to the gear with the power output. The efficiency represents the ratio of the output power to the input power, expressed as a percentage. Here’s a detailed explanation of how to calculate the efficiency of a helical gear: The formula for calculating gear efficiency is:

To calculate the efficiency, you need to determine the power input and power output values. Here are the steps involved:

The resulting efficiency value will be a percentage, representing the proportion of input power that is effectively transmitted as output power by the helical gear system. A higher efficiency value indicates a more efficient gear system, with less power loss during the gear transmission. It’s important to note that gear efficiency can be influenced by various factors, including gear design, tooth profile, operating conditions, lubrication, and manufacturing quality. Therefore, the calculated efficiency represents an estimate based on the given input and output power values, and it may vary in real-world applications.

What are the applications of helical gears?Helical gears find wide-ranging applications in various mechanical systems due to their advantageous characteristics and capabilities. Here’s a detailed explanation of the applications of helical gears: 1. Power Transmission: Helical gears are commonly used for power transmission in a wide range of industries. They are employed in machinery and equipment where rotational motion needs to be transmitted between parallel shafts. Examples include gearboxes, industrial machinery, conveyors, and automotive transmissions. 2. Rotary Motion Control: Helical gears are used in applications where precise rotary motion control is required. They provide smooth and accurate motion transfer, making them suitable for applications such as robotics, precision equipment, machine tools, and positioning systems. 3. High Torque Applications: Due to their design and tooth engagement characteristics, helical gears are well-suited for high torque applications. They can efficiently transmit substantial power and handle heavy loads. This makes them suitable for heavy machinery, construction equipment, mining machinery, and marine propulsion systems. 4. Automotive Industry: Helical gears are extensively used in automotive applications. They are found in transmissions, differentials, and powertrain systems, where they facilitate smooth and efficient power transmission while reducing noise and vibration. Helical gears help achieve the desired gear ratios and torque multiplication in vehicles. 5. Machine Tools: Machine tools, such as milling machines, lathes, and gear hobbing machines, utilize helical gears for precise motion control and power transmission. Helical gears enable accurate and smooth rotation of cutting tools and workpieces, contributing to the high precision and quality of machined components. 6. Printing Industry: Helical gears are used in printing presses and other printing equipment. They facilitate the precise movement of paper and printing plates, ensuring accurate registration and high-quality printing results. 7. Textile Industry: In the textile industry, helical gears are employed in various machinery and equipment. They are used in spinning machines, weaving machines, and other textile processing equipment that require precise motion control and power transmission for efficient textile production. 8. Oil and Gas Industry: Helical gears are utilized in oil and gas equipment and machinery. They are found in pumps, compressors, drilling rigs, and other critical components where high torque transmission and reliable motion control are essential for efficient operations. 9. Power Generation: Helical gears play a crucial role in power generation systems. They are employed in wind turbines, hydroelectric generators, and other power generation equipment to transmit rotational motion from the turbine or generator shaft to the electrical generator, ensuring efficient electricity production. 10. General Machinery: Helical gears have diverse applications in general machinery across various industries. They are used in packaging equipment, food processing machinery, material handling systems, and numerous other mechanical systems that require reliable power transmission and precise motion control. The versatility, load-carrying capacity, and smooth operation of helical gears make them suitable for numerous applications in different industries. The specific design, tooth profile, helix angle, and material selection can be tailored to meet the requirements of each application, ensuring optimal performance and longevity of the gear system.

China manufacturer Machining Transmission Bevel Gear Helical Gears for Auto with Hot sellingProduct Description

OEM machining Transmission Bevel Gear Helical Gears for Auto Parts

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the advantages and disadvantages of using helical gears?Helical gears offer several advantages and disadvantages compared to other types of gears. It’s important to consider these factors when selecting the appropriate gear type for a specific application. Here’s a detailed overview of the advantages and disadvantages of using helical gears: Advantages of Helical Gears:

Disadvantages of Helical Gears:

Considering these advantages and disadvantages, engineers can make informed decisions when selecting helical gears for their specific applications. By carefully evaluating the requirements and constraints of the system, they can leverage the strengths of helical gears while mitigating any potential limitations.

Can helical gears be used in heavy-duty machinery and equipment?Yes, helical gears can be used in heavy-duty machinery and equipment. The design characteristics of helical gears make them well-suited for demanding applications that involve high loads, high speeds, and continuous operation. Here’s a detailed explanation of why helical gears are suitable for heavy-duty machinery and equipment:

In summary, helical gears are well-suited for heavy-duty machinery and equipment due to their load distribution capabilities, smooth operation, high efficiency, adaptability to different sizes and ratios, compatibility with high speeds, ability to handle shock loads, compatibility with lubrication systems, and the manufacturing expertise available for their production. These factors make helical gears a reliable choice for heavy-duty applications across various industries.

What are the benefits of using a helical gear mechanism?A helical gear mechanism offers several benefits that make it a preferred choice in many applications. Here’s a detailed explanation of the advantages of using a helical gear mechanism:

In summary, the benefits of using a helical gear mechanism include smooth and quiet operation, high load-carrying capacity, efficient power transmission, versatility, improved tooth strength, compact design, and high mechanical efficiency. These advantages make helical gears suitable for a wide range of applications, including automotive transmissions, industrial machinery, power generation equipment, robotics, and more.

China best Engineering Injection Mould Big UHMW PE Large Plastic Worm Gear supplierProduct Description

Our Services

Product Design Material Selection

Detail Image Why Choose Us Our Machine Product Range Contact Us /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the advantages and disadvantages of using a worm gear?A worm gear offers several advantages and disadvantages that should be considered when selecting it for a specific application. Here’s a detailed explanation of the advantages and disadvantages of using a worm gear: Advantages of using a worm gear:

Disadvantages of using a worm gear:

When considering the use of a worm gear, it’s essential to evaluate the specific requirements of the application and weigh the advantages against the disadvantages. Factors such as torque requirements, speed limitations, positional stability, space constraints, and overall system efficiency should be taken into account to determine if a worm gear is the right choice.

How do you retrofit an existing mechanical system with a worm gear?When retrofitting an existing mechanical system with a worm gear, several considerations need to be taken into account. Here’s a detailed explanation of the retrofitting process:

It’s important to note that retrofitting an existing mechanical system with a worm gear requires expertise in mechanical engineering and an understanding of the specific system requirements. If you lack the necessary knowledge or experience, it is advisable to consult with professionals or engineers specializing in power transmission systems to ensure a successful retrofit.

Understanding Worm Gears and Their OperationA worm gear is a type of mechanical gear that consists of a threaded screw-like component (called the worm) and a toothed wheel (called the worm gear). It is used to transmit motion between non-intersecting and perpendicular shafts. Here’s how it works: The worm, typically in the form of a cylindrical rod with a helical thread, meshes with the teeth of the worm gear. When the worm is rotated, its threads engage with the teeth of the worm gear, causing the gear to rotate. The direction of rotation of the worm gear is perpendicular to the axis of the worm. One significant feature of worm gears is their ability to provide high gear reduction ratios. The number of teeth on the worm gear relative to the number of threads on the worm determines the reduction ratio. This makes worm gears suitable for applications where high torque and low-speed rotation are required. Worm gears are commonly used in various mechanical systems, such as conveyor systems, lifts, automotive steering mechanisms, and more. Their unique design also provides a self-locking feature: when the system is not actively rotating the worm, the gear cannot easily backdrive the worm due to the angle of the threads, providing mechanical advantage and preventing reverse motion.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||